Hakko 192 Soldering Tester Manual

One tester for all your soldering iron maintenance needs. What should you check when doing a daily inspection of your soldering iron? Grounded soldering irons are maintained by inspecting leak voltage, tip-to ground resistance, and tip temperature. Grounded soldering irons cannot be maintained by checking insulation resistance. This method was used in the past in order to find out the level of leak current.

Yes, the Hakko 192 Tester can be used to validate tip temperature, tip-to-ground potential (leak voltage) and tip-to-ground resistance with any soldering iron.

What is 'Leak voltage'? Leak current is the current that leaks from the tip to a board or device. Leak voltage is a specific measurement of the level of this current. The leakage can adversely affect delicate devices, so it is necessary to check leak voltage on a daily basis. Maximun current value mesured with HAKKO FG-101 100V-120V Spec 5A 220V-240V Spec 3A Note: HAKKO FG-101 is broken when beyond maximum current value is measured.

In addition to traditional features, the FG-101 comes with two new functions: MAX HOLD and AUTO ZERO. MAX HOLD Function Constantly displays the maximum temperature AUTOZERO Function Automatically corrects zero point error of measuring instruments Traditional Features Lead-free sensor Measures leak voltage by True Root Mean Square (TRMS) Highly reliable - Resistant to drift and changes in temperature. The FG-101 does not come with the Monitor Output function that was included in past models.

Check 1 Check 2 Check 3 Check 4 Check 5 Is the correct measurement method suitable for the measuring instrument being performed? Is the correct measurement method suitable for the measuring instrument being performed? If the wrong method is performed for measurements, the correct temperature is not obtained in some cases.

Measure the temperature with the correct method suitable for the measuring instrument again. If the temperature is still shown lower, confirm the details in Checks 1 through 4. Correctly measuring the tip temperature We HAKKO recommend that the same tip undergoes measurement several times and the measured maximum temperature is adopted as a correct tip temperature. Since the temperature may be displayed lower for I-type and 1C-type tips whose tip end is thin in particular, take sufficient time for measurement and read the temperature when the displayed data are stable.

NOTE If a measuring instrument manufactured by another company is used, refer to its instruction manual. Remove solder stuck on the tip before measurement. Apply new solder in the tip. Place the tip on the measuring point and apply solder to it. NOTE The sensor also becomes deteriorated gradually as the number of measuring times increases, causing the correct temperature not to be obtained. At this time, if too much solder is applied to the tip, heat will be absorbed by the solder, causing the correct temperature not to be obtained. The way of placing the tip to the measuring point should be changed depending on the tip shape.

Chess pc game free download - Chess Rally, Chess 2020, Champion Chess, and many more programs. The best chess games to play online or offline on PC. Free Chess, free and safe download. Free Chess latest version: Free Chess. Free Chess is an elegant game for exactly that, playing chess, without any complicated.

Chess pc game free download - Chess Rally, Chess 2020, Champion Chess, and many more programs. The best chess games to play online or offline on PC. Free Chess, free and safe download. Free Chess latest version: Free Chess. Free Chess is an elegant game for exactly that, playing chess, without any complicated.

For further details, refer to 'Points for measurement' shown below. The photo shows an example where the T12-B type is used. Do not touch the slide pin which is weak to high temperature by tip nor solder directly. Read the displayed values. (The photo shows 376ºC.) 5. Repeat the items 1 through 4.

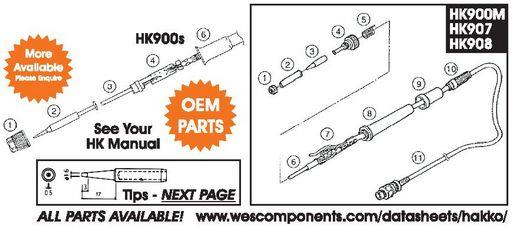

Hakko Soldering Gun

Check the maximum temperature. Points for measurement Placing the tip on the measuring point horizontally enables the correct temperature measurement. For the B type, I type and D type, in the case of a tip with standard solder plating, place the center of the solder plating to the measuring point as shown left. For the BC type and C type, in the case of a face with solder plating, place the plated face to the measuring point as shown above. CAUTION: It is impossible to measure while applying hot air of Hot Air Rework System (, etc.) directly.

Use the Temperature Probe (No. C1541) specifically for Hot Air Rework Systems.