Install Clutch Spring Club Car

What Goes Wrong & Why: Basically things wear out. Some of the problem areas you can visually check & lubricate or repair as needed but over time, especially with severe use & little maintenance the parts just start wearing out. Rebuilding drive clutches used to be a common practice but the time & parts invested and the poor serviceability after all the effort proved to be unacceptable. Driven units are more commonly rebuilt depending on the brand of golf cart and the failure. This doesn’t mean you cannot extend the life of the clutch system you now have. Don’t blame the clutch system for engine problems (garbage in, garbage out) and don’t overlook their effect on a smooth ride.

The clutches should gradually transition, or ‘shift gears’, during start up and acceleration, remain steady while cruising at top speed and smoothly downshift when beginning a hill climb or coming to a stop. They should not jump, jerk, vibrate, wobble or cause the belt to bark upon startup.

Does any of this sound familiar? A common question asked of our techies and addressed in our forum has to do with the hill pulling capability of gas golf carts. A golf cart is designed by the manufacturer to carry 800 lbs of passengers & golf bags around a fairly steep golf course and when they are new they do a very good job for several years. As time and maintenance slip away, the rounds of golf take their toll.

Clutch & engine wear and lease termination eventually send the cart to be recycled. This is where you, the buyer, comes in. Not every used golf cart is poorly maintained, in fact many courses take excellent care of their carts, but gas engines & their clutches take a beating, especially at busy courses. Buying a used gas cart is a crap shoot.

Club Car Clutch found in: Club Car Driven Clutch Reversed Spring FE350 (Fits 1998-Up), Club Car DS / Precedent Gas Drive Clutch (Fits 1988-Up), Club.

- Find great deals on eBay for club car driven clutch and club car driven clutch kit. Shop with confidence.

- Club Car Clutch found in: Club Car Driven Clutch Reversed Spring FE350 (Fits 1998-Up), Club Car DS / Precedent Gas Drive Clutch (Fits 1988-Up), Club.

Both you and the dealer (if he stands behind the product) are gambling nothing goes wrong for an acceptable period of time. You expect some repair will be needed down the road but hopefully the dealer found & repaired most of the trouble before he sold you the cart. The fact is that gas golf cars are tremendously durable & long lived, usually with few major problems, assuming reasonable care.

Power, especially during hill climbs, and/or carrying four passengers, requires a strong engine and a good clutch system. When used primarily on level terrain either system, or both, can be in marginal condition and yet still be acceptable for the intended use. Take that same cart to a steep hill and the tale will be told; if performance declines to an unacceptable level, you must determine if the clutches or the engine is at fault. A strong engine requires regular tune-ups including oil & filter changes & spark plugs.

The battery, electrical & ignition system must be reasonably maintained and in good condition. The spark to the plug(s) must be strong and applied at a very precise moment. Fuel supply lines, the fuel pump, actuator cables and the carburetor all must be clean and properly adjusted to correctly meter the fuel to the engine. The carburetor mixes droplets of gasoline into a very precise amount of air, which the engine can effectively burn. The piston and piston rings must create enough compression in the cylinder to efficiently burn the air/fuel mix and to create enough vacuum in the bottom end to power the fuel pump. This means crankcase seals and gaskets must maintain sufficient integrity. The brakes must not be dragging due to a kinked cable or frozen shoe, and the tires should have about 20psi.

Not really much to go wrong here. And besides, I will write more about good engines/bad engines at another time. Let’s move on to clutches. Drive Clutches As mentioned before, parts just start to wear outsome you can repair, some you cannot.

With a bad drive clutch, unless you have a Yamaha, your goose is pretty well cooked. Yamaha used to employ three articulating flyweights, which were subject to break over time. Sometimes the broken flyweight flings outward and cracks the side of the metal cover used to protect them from dirt & water contamination. Sometimes one can observe a crack in the cover, or one that has been welded over (not a good idea).

When one of the flyweights breaks it has a pronounced effect on the pulling power of the cart. The speed transition remains fair but the engine just doesn’t seem to pull well, especially uphill. It’s not the engine! It’s the drive clutch.

There is more to drive clutch problems than just bad flyweights, which can make excessive noise or totally lock up & prevent the sheaves from opening or closing at all. Additionally, the sliding sheave inner bushing and the shaft it rides along wear a small amount but it is enough to cause a slight wobbling of the sliding sheave as it moves in & out along the shaft. Visual evidence of this is feathering at the very outer edges of the drive belt–the edges curl up–more about belts later). Again, Yamaha use to provide a grease nipple to lubricate these bushings & the main shaft but Yamaha was the exception, not the rule. You can apply a thin coat of spray lube or thin grease to the shafts & bushings of other clutch systems and this may help extend the life of these expensive units, but you just may be buying time. Caution: too much lube can gum up the works creating more problems then it fixes and NEVER use a spray-type belt dressing on the drive belt. Only the old Harley Davidson carts used a wet drive clutch.

About 8 ounces of 90-weight gear oil was used to keep things moving smoothly. These wet drive units were also subject to the failures described herein and others not yet addressed. After 1981 all golf cart clutch systems were dry, except the Yamaha clutches which could be greased but they were never really a ‘wet’ clutch (don’t over-grease them-one or two pumps of grease is all they need). Another common clutch problem is the ‘soft’ clutch faces wearing out due to the constant action of the belt edges scrubbing against them. One sheave of each clutch slides in & out along its central shaft but they both spin; the drive unit spins at the same RPM of the engine and the driven spins at various rates depending on the engine RPM.

Each time the engine starts up (perhaps a thousand times a day at a busy golf course) the drive clutch starts to spin before the belt is actually engaged (permits easy starting-see below). Start up & hill climbs are when the clutches & belt work the hardest and the belt slippage, over time, begins to wear a groove in the soft aluminum clutch faces. You can see & feel the grooves (or dishing, as I call it) by looking at, or rubbing your fingertips up & down, the clutch face. This is easier to see & feel on the drive unit because the faces are separated when at rest but both clutches are affected. The faces should be ruler straight; as little as.060” (sixty thousandths) dishing is considered maximum wear on either clutch.

Badly dished clutch faces coupled with a badly worn belt can cause a significant loss of pulling ability, which often gets blamed on the engine. If there is severe dishing down low near the center of the drive clutch faces, the belt may actually bark upon start up as it slips into the deep groove and momentarily loses traction. At top speed the belt will eventually wear a groove around the upper portion of the clutch face too. In the old Harleys sometimes a groove wears so deep that hairline cracks develop in the soft sheave face and oil bleeds through contaminating the belt and creating excessive belt slippage.

Today the clutch systems are quite reliable but as they age all kinds of strange things can happen. Excessive ‘slapping’ noise upon start up and while the engine winds down to near stop can indicate a drive clutch nearing the end of its useful life—worn bushing, shaft & flyweights. Or the drive unit may lock up in the high speed position causing the cart to lurch & jerk when trying to start; the sheaves do not separate as intended, which puts the belt in a very tight bind. As the engine cranks over & tries to start, the belt is already engaged so the cart is actually dragged along by the cranking action until the engine fires.

A weak battery or trying to start while headed up hill makes the whole situation worse, if not impossible. Another symptom of impending drive clutch failure is poor transition from top speed to hill pulling.

You are riding along on level or near level ground at top speed; the engine is running fine with reasonable power. As you start up a steep incline the car slows to a crawl then suddenly the drive clutch pops open releasing the belt and the car magically starts to pull up the hill.

It’s the drive clutch, not the engine. Almost all gas carts will slow down some when beginning a hill climb.

This is natural, but if the drive clutch functions correctly it opens and closes smoothly to adapt to various terrains. The factors discussed above eventually may cause the drive unit to lock up temporarily, sometimes permanently. As the prophet on the street corner says”The end is near”. Uneven operation during acceleration and at cruising speed may be a sign of driven clutch problems. We look there next.

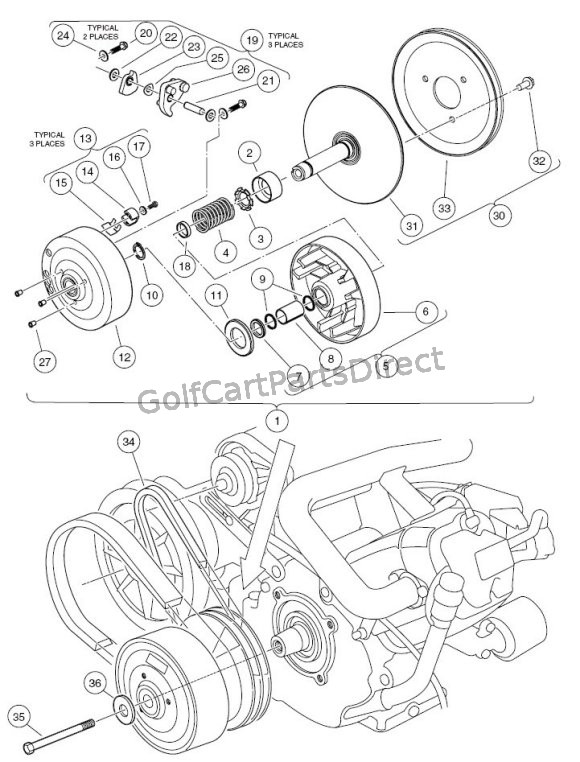

Driven Clutches as They Relate to the Drive The other half of this clutch system is the driven, or secondary, clutch. At rest the driven clutch sheaves are spring loaded together, so the belt rides up at the outer edge of this clutch, NOT down near the center shaft. The driven unit spins around and also has a sheave that sides in & out along a main shaft but this clutch has no flyweights.

It works only when acted upon by the force of the drive belt. As the engine spins, forcing drive clutch sheaves together, the belt moves higher on the clutch faces. This belt action, in turn, forces the driven clutch sheaves to separate, allowing the belt to ride closer to the center shaft of the driven unit. In other words, as the drive clutch sheaves come together the belt causes the driven clutch sheaves to separate. This give and take between the clutches, via the belt action, is what gives the car variable speedsan automatic transmission, so to speak. As the drive belt forces the driven clutch sheaves to separate, the PULLING ratio of the engine changes from maximum torque (when the belt is at the outer edge of the driven unit) to minimum PULLING power, (top cruising speed) when the driven sheaves are completely apart. The driven clutch can misbehave in many ways.

It has one main shaft and a sliding sheave with an internal bushing that will wear, and it has several inclined metal ramps (usually aluminum) with small plastic buttons that protect the ramps as they glide against one another. Frequently the buttons wear completely down or break & the metal ramps start to rub directly against each other. It’s not long before the speed transition becomes very poor and permanent damage is done to the driven clutch. During the next session we will go into what goes wrong with the driven clutches and why. For now take a look that the Yamaha information below.

Yamaha Driven Clutch: You can easily see these ramps by looking just inboard of the large driven clutch sheaves. You will see a central spring enclosed on each end by a funky looking cup with 3 pyramid shaped cones on the sides of each cup. These cones are the ramps I mentioned above and they interlace and interface with each other. On the outer tip of each cone SHOULD be a small flat button (2 cycle cars have 6 buttons total, 4 cycles have 3. Originally they were white).

The buttons prevent the metal ramps from rubbing against one another as the sheave moves in and out. The engine revs up and the drive belt starts to ride down into the pulley faces of the driven clutch forcing them to separate. The inboard pulley half begins to slide along the main shaft compressing the spring and bringing the funky cup ends and their respective ramps up against one another. The small plastic buttons actually come between the metal ramps to protect them and allow them to smoothly glide in & out against each other. Sometimes one or two buttons may be gone and the whole thing still works pretty well, but not for long! When all the buttons are missing the aluminum ramps wear against each other and soon the clutch can no longer function properly.

Level running may be fair but performance under heavy loads or hill climbs is very difficult. Another failure that occurs is almost impossible to detect but it, too, impairs the pulling power of the car. Keep looking inboard to where the funky spring cap butts up against the differential housing. The spring cap doesn’t actually touch the differential case, but there should be enough of a gap that you can insert your pointer finger between the spring cap and the diff case. (Please don’t try this with the clutch spinning.

Key off.) What happens is that a small, difficult to see, snap ring, that keeps proper tension on the main clutch spring, comes out of a machined groove in the differential input shaft. When the snap ring goes south it causes the main spring to lose much of its tension. Once the snap ring comes out a new one will NOT stay in the groove. A special collar (link) must be installed in place of the snap ring.

The alternative is to dissemble the differential, replace the input shaft and reinstall everything back into the car. You will need to dissemble the driven clutch to install this special collar but this is much preferable to the alternative. Written by John C. Triolo, President, www.GolfCarCatalog.com This entry was posted in.

Bookmark the. Before spending a lot of money on a new drive clutch, I’d try check a couple less expensive items also. First, if you have not replaced the belts in a while, I would replace both the drive belt and starter/generator belt. They are inexpensive compared to the drive clutch and they do wear down as they are used. The starter belt especially comes to mind as they are very common to make this noise. The starter belt should be VERY tight.

So tight that you can barely make it bend by applying pressure with your hand. If it’s not, use the adjust mechanisms in the cart to tighten. If it’s not super tight, it will squeal especially under a load. If your drive belt is old and/or worn, it could also cause an issue of this nature under a load.

As the thickness of the belt decreases, the vehicle loses power. I’d check and replace these belts if needed before getting into the clutch. As a side note, the driven or secondary clutch (on the differential) is usually the clutch that has the greatest effect on pulling power. You might want to give it a glance for a few signs of problems. Check the faces of the clutch where the belt rides to be sure no significant “grooving” has occurred.

Also, check the spring within to be sure it’s not broken. And last, be sure to look at the ramp buttons for significant wear. We have several clutch articles within our blog which may be of further assistance.

Please let me know if I can help further. Bob, Before dumping too much money into this, I’d give something a shot.

Club Car Clutch Repair

First, let me say when I hear the term “barking” form a golf cart belt, I automatically think of the starter/generator belt. Unlike the drive belt which is very loose when not engaged, the starter belt should be very tight, otherwise squealing may occur. It would not, however, hinder the pulling power. I’d also recommend going up a hill and pulling out your choke. If it improves the power, you have a fuel problem, not a clutch issue. If it does not help, you likely have a clutch or belt issue.

It has been my experience that the driven or secondary clutch usually has more effect than the drive clutch, but it’s not always the case. If it were me, I’d replace the driven instead of the drive clutch for pulling power any day. Check the faces of both clutches where the belt rides. There should not be grooving in the faces. Also, on the driven clutch, check to be sure the internal spring is not broken, as well as check the length of the ramp shoe buttons. They are plastic buttons which prevent metal on metal wear between the “teeth” on the cam. If worn, replace and that may help tremendously.

Hope this helps. Occasionally, you might have to do some slight modification on the ramp buttons as well as the holes into which they are pressed. I’ve broken many of these press-in style of buttons over the years.

First, be sure you are lined up and prepared to go straight into the hole. Since they are plastic, it is easy to get it slightly crooked and then when you try to press or drive it in, the plastic beg will bend or break.

Also, you might need to use a utility knife to lightly shave just a very small amount off the diameter of the peg to make it fit. Lastly, if that doesn’t work, we have occasionally used a drill bit on the hole into which the ramp button fits. You want to select a drill bit which is only slightly bigger than the hole itself.

Club Car Clutch Parts

You only want to take as little material out of the hole as possible because once it’s out. You can’t put it back. I would also do it with a hand drill instead of a power drill to ensure you don’t wallow it out or slip. Another method would be to use a small round file to gently clean up any burrs from around the the hole and to enlarge it by only the smallest amount.